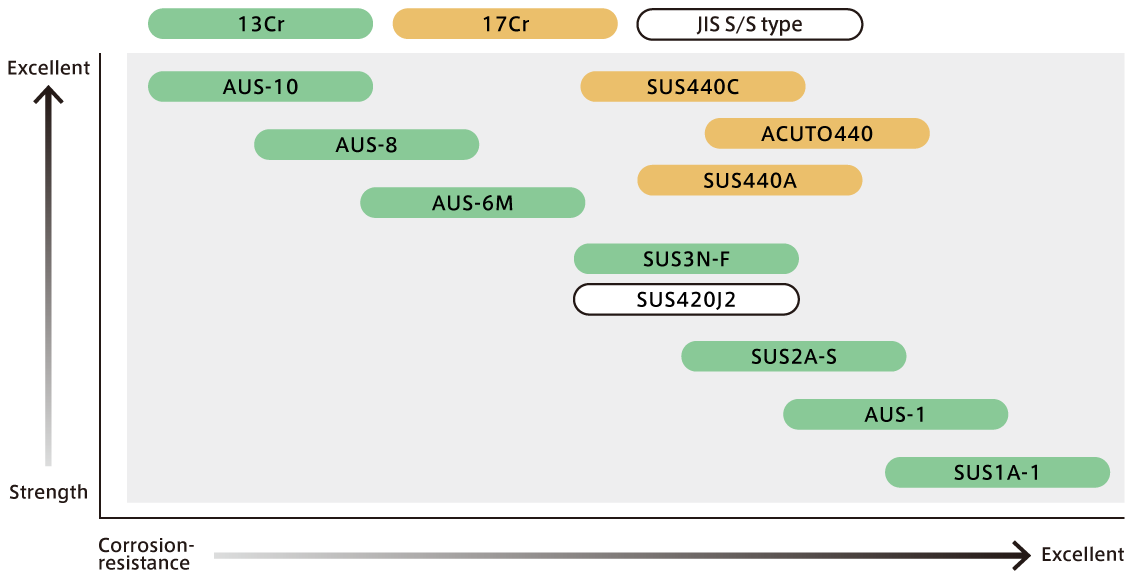

Characteristics and example use

| Classification | Characteristics and example use | |

| 13Cr | SUS1A-1 | SUS1A-1 has the least amount of carbon among 13 chrome steels. As a result, among 13 chrome steels,SUS1A-1, has superior corrosion resistance with cold rolling and welding ability. AUS-1, SUS2A-S are increased carbon contents,improved heat treatment hardness and wear resistance. Use is medical equipment and others. |

|---|---|---|

| AUS-1 | ||

| SUS2A-S | ||

| SUS3N-F | Add sulfur to SUS420J2, improved machinebility. Use is gauges. | |

| SUS420J2 | JIS steel type,uses are popular knives,gauges. | |

| AUS-6M | AUS-6M,AUS-8 and AUS-10 are increased more carbon contents,added vanadium and molybdenum,improved more hardness,wear resistance,annealing resistance. Uses are high-quality knife,scissors,pocket knife,medical equipment, food machine,mechanical parts and more. | |

| AUS-8 | ||

| AUS-10 | ||

| 17Cr | SUS440A | These steels have corrosion-resistance and wear resistance at the same time. Improve wear resistance 1.SUS440A 2.ACUTO440 3.SUS440C(improving wear resistance) Uses are high-quality knife,hairdressing or cosmetic scissors,medical equipment, gauges,food machine,mechanical parts,automobile parts and more. |

| ACUTO440 | ||

| SUS440C |

Size of products

Hot rolling sheet

| Classification | S/S type | Size of products (mm) | ||||

| Thickness ※1 |

Width | Length ※2 |

||||

| 230 | 250 | |||||

| 13Cr | SUS1A-1 | 6.0- 20.0 |

– | ○ | 1,000- 4,000 |

|

|---|---|---|---|---|---|---|

| AUS-1 | – | ○ | ||||

| SUS2A-S | – | ○ | ||||

| SUS3N-F | ○ | ○ | ||||

| SUS420J2 | – | ○ | ||||

| AUS-4 | ○ | ○ | ||||

| AUS-6M | ○ | ○ | ||||

| AUS-8 | ○ | ○ | ||||

| AUS-10 | ○ | ○ | ||||

| 17Cr | SUS440A | ○ | – | |||

| ACUTO440 | ○ | ○ | ||||

| SUS440C | ○ | ○ | ||||

※1 Possible to manufacture each 1.0mm thickness.

※2 Possible to cut any length,but we have basic length by thickness.

Cold rolling sheet

| Classification | S/S type | Size of products (mm) | ||||

| Thickness ※3 |

Width ※4 |

Length ※5 |

||||

| 230 | 250 | |||||

| 13Cr | SUS1A-1 | 0.8- 10.0 |

– | ○ | 1,000- 2,800 |

|

|---|---|---|---|---|---|---|

| AUS-1 | – | ○ | ||||

| SUS2A-S | – | ○ | ||||

| SUS3N-F | ○ | ○ | ||||

| SUS420J2 | – | ○ | ||||

| AUS-4 | ○ | ○ | ||||

| AUS-6M | ○ | ○ | ||||

| AUS-8 | ○ | ○ | ||||

| AUS-10 | ○ | ○ | ||||

| 17Cr | SUS440A | ○ | – | |||

| ACUTO440 | ○ | ○ | ||||

| SUS440C | ○ | ○ | ||||

※3 Possible to manufacture each 1.0mm thickness.

※4 Possible to cut any length,but we have basic length by thickness.

Mechanical property and chemical component

Mechanical property

| Classification | S/S type | Tension test | Hardness test | Charpy impact test |

|||

| 0.2% bearing (N/㎟) |

Tensile strength (N/㎟) |

Growth (%) |

Drawing (%) |

Hardness (HV20) |

Energy KV2 (J) |

||

| 13Cr | SUS1A-1 | 269 | 428 | 40 | 84 | 135 | 116 |

|---|---|---|---|---|---|---|---|

| AUS-1 | 285 | 553 | 36 | 80 | 167 | 255 | |

| SUS2A-S | 352 | 627 | 30 | 67 | 181 | 35 | |

| SUS3N-F | 304 | 620 | 29 | 64 | 179 | 40 | |

| SUS420J2 | 354 | 648 | 32 | 63 | 187 | 31 | |

| AUS-4 | 314 | 676 | 29 | 63 | 196 | 23 | |

| AUS-6M | 367 | 750 | 26 | 53 | 221 | 13 | |

| AUS-8 | 389 | 795 | 23 | 39 | 236 | 13 | |

| AUS-10 | 320 | 778 | 22 | 40 | 233 | 10 | |

| 17Cr | SUS440A | 468 | 825 | 21 | 39 | 248 | 12 |

| ACUTO440 | 478 | 826 | 17 | 24 | 260 | 7 | |

| SUS440C | 377 | 821 | 16 | 22 | 254 | 5 | |

Chemical component

| Classification | S/S type | Chemical component (%) | ||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | V | ||

| 13Cr | SUS1A-1 | ≦0.08 | ≦0.7 | ≦1.0 | ≦0.04 | ≦0.03 | ≦0.49 | 13.00- 14.50 |

≦0.6 | - |

|---|---|---|---|---|---|---|---|---|---|---|

| AUS-1 | 0.09- 0.13 |

≦0.4 | ≦1.0 | ≦0.04 | ≦0.015 | ≦0.60 | 12.00- 13.00 |

≦0.6 | - | |

| SUS2A-S | 0.23- 0.28 |

≦1.0 | ≦1.0 | ≦0.04 | ≦0.03 | ≦0.30 | 13.00- 14.50 |

≦0.6 | - | |

| SUS3N-F | 0.33- 0.37 |

0.40- 0.70 |

0.50- 0.90 |

≦0.04 | 0.07-0.11 | ≦0.30 | 13.00- 14.50 |

≦0.6 | - | |

| SUS420J2 | 0.26- 0.40 |

1.00以下 | ≦1.0 | ≦0.04 | ≦0.003 | ≦0.60 | 12.00- 14.00 |

≦0.60 | - | |

| AUS-4 | 0.40- 0.45 |

≦0.8 | ≦1.0 | ≦0.04 | ≦0.005 | ≦0.30 | 13.00- 14.50 |

≦0.6 | - | |

| AUS-6M | 0.55- 0.65 |

≦0.8 | ≦0.85 | ≦0.04 | ≦0.005 | ≦0.30 | 13.00- 14.50 |

0.10- 0.30 |

0.10- 0.25 |

|

| AUS-8 | 0.70- 0.80 |

≦0.8 | ≦0.50 | ≦0.04 | ≦0.005 | ≦0.30 | 13.00- 14.50 |

0.10- 0.30 |

0.10- 0.25 |

|

| AUS-10 | 0.95- 1.10 |

≦0.8 | ≦1.0 | ≦0.04 | ≦0.005 | ≦0.30 | 13.00- 14.50 |

0.10- 0.30 |

0.10- 0.25 |

|

| 17Cr | SUS440A | 0.60- 0.75 |

≦0.8 | ≦1.0 | ≦0.04 | ≦0.005 | ≦0.30 | 16.00- 18.00 |

0.30- 0.75 |

- |

| ACUTO440 | 0.80- 0.95 |

0.35- 0.50 |

0.25- 0.40 |

≦0.04 | ≦0.03 | ≦0.25 | 17.00- 18.00 |

1.00- 1.25 |

0.08- 0.12 |

|

| SUS440C | 0.95- 1.20 |

≦0.8 | ≦1.0 | ≦0.04 | ≦0.005 | ≦0.30 | 16.00- 18.00 |

≦0.75 | - | |

Strength and corrosion-resistant

Strength and corrosion-resistant

| Classification | S/S type | Target temperature of heat treat (℃) | Reference of quenching- tempering strength(HRC) |

||

| Annealing | Quenching | Tempering | |||

| 13Cr | SUS1A-1 | 850 slow cooling |

1050 oil p or air cooling |

180 | 18.6 |

|---|---|---|---|---|---|

| AUS-1 | 56.0 | ||||

| SUS2A-S | - | ||||

| SUS3N-F | 57.3 | ||||

| SUS420J2 | 57.3 | ||||

| AUS-6M | 58.0 | ||||

| AUS-8 | 59.0 | ||||

| AUS-10 | 60.0 | ||||

| 17Cr | SUS440A | 58.0 | |||

| ACUTO440 | 1070℃ | 58.0 | |||

| SUS440C | 1050℃ | 60.0 | |||