Processing results

| Classification | Specificexamples |

| Ti alloy | Golf club,shape memory alloy |

|---|---|

| Al alloy | Many kinds |

| Mg alloy | AZ31 |

| Cu alloy | Cu-Fe,Cu-Ni |

| Electromagnetic alloy | Ni-Fe,Permalloy,others |

| Anticorrosive alloy | Inconel,Monel |

| Heat-proof alloy | Ni-based,Co-based |

| Pure metal | Ti,Mo,Nb,Ta,others |

| Special clad steel | SUS-Ti,Cu-SUS,others |

| Powder high-speed steel | SUS series,High-speed metal series,others |

| Others | Spring,Dies steel,others |

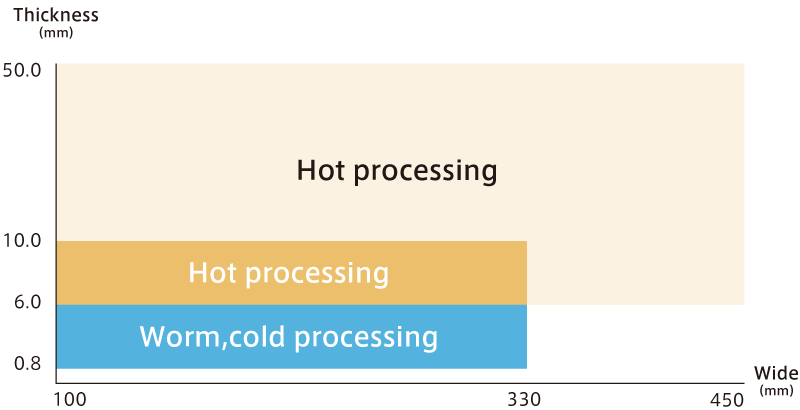

Possible rolling size

| Processing temp. zone | ||

| Hot processing |

800-1240℃ | 1470-2260°F |

|---|---|---|

| Warm processing |

100-800℃ | 210-1470°F |

| Cold processing |

Ordinary tenmperature | |

Appurtenant Secondary Finish

Wet Blast

Provides even higher quality surface finishes than acid pickling or shot blast.

Cutting

Formed into a shape as close to the finished product as possible by processing rolled material.

Straightening

Large-scale flat plates are straigtened using stretchers and roll straightening.

Grinding

Final surface finshing is performed by using, flat grinding, and wet flap wheel grinding.